小裂紋的擴展是導(dǎo)致結(jié)構(gòu)部件進入疲勞期的主要因素。盡管人們對此有很大的興趣,但就裂縫擴展的方向和速度而言,小裂縫的生長指標尚未確定。

由美國普渡大學(xué)Michael Sangid領(lǐng)導(dǎo)的團隊,提出了一種識別微結(jié)構(gòu)小疲勞裂紋驅(qū)動力的新方法。他們采用機器學(xué)習(xí)建立了兩個獨立的貝葉斯網(wǎng)絡(luò),分析了鈦合金原位疲勞循環(huán)過程中獲得的衍射數(shù)據(jù)和X線斷層影像數(shù)據(jù)。該方法能識別影響疲勞裂紋擴展方向和擴展速率的微機械和微結(jié)構(gòu)變量。他們發(fā)現(xiàn),第一主應(yīng)力軸在特定方向上的取向和最大分辨剪切應(yīng)力與裂紋擴展最為相關(guān),將其納入關(guān)系分析中可以描述裂紋擴展方向的概率。他們的分析模型可靠地預(yù)測了小裂紋擴展的方向,再現(xiàn)了實驗結(jié)果,比之前文獻的預(yù)測更為可靠。這種半監(jiān)督機器學(xué)習(xí)方法不僅可以識別鈦合金中小裂紋擴展方向背后的復(fù)雜變量,也有望識別其他復(fù)雜工程問題中的驅(qū)動力。

Using machine learning and a data-driven approach to identify the small fatigue crack driving force in polycrystalline materials

Andrea Rovinelli, Michael D. Sangid, Henry Proudhon & Wolfgang Ludwig

The propagation of small cracks contributes to the majority of the fatigue lifetime for structural components. Despite significant interest, criteria for the growth of small cracks, in terms of the direction and speed of crack advancement, have not yet been determined. In this work, a new approach to identify the microstructurally small fatigue crack driving force is presented. Bayesian network and machine learning techniques are utilized to identify relevant micromechanical and microstructural variables that influence the direction and rate of the fatigue crack propagation. A multimodal dataset, combining results from a high-resolution 4D experiment of a small crack propagating in situ within a polycrystalline aggregate and crystal plasticity simulations, is used to provide training data. The relevant variables form the basis for analytical expressions thus representing the small crack driving force in terms of a direction and a rate equation. The ability of the proposed expressions to capture the observed experimental behavior is quantified and compared to the results directly from the Bayesian network and from fatigue metrics that are common in the literature. Results indicate that the direction of small crack propagation can be reliably predicted using the proposed analytical model and compares more favorably than other fatigue metrics.

-

數(shù)據(jù)驅(qū)動

+關(guān)注

關(guān)注

0文章

141瀏覽量

12579 -

貝葉斯網(wǎng)絡(luò)

+關(guān)注

關(guān)注

0文章

24瀏覽量

8407 -

機器學(xué)習(xí)

+關(guān)注

關(guān)注

66文章

8503瀏覽量

134596

原文標題:npj: 機器學(xué)習(xí)-數(shù)據(jù)驅(qū)動:裂縫擴展的微機械變量識別

文章出處:【微信號:zhishexueshuquan,微信公眾號:知社學(xué)術(shù)圈】歡迎添加關(guān)注!文章轉(zhuǎn)載請注明出處。

發(fā)布評論請先 登錄

【下載】《機器學(xué)習(xí)》+《機器學(xué)習(xí)實戰(zhàn)》

基于深度學(xué)習(xí)技術(shù)的智能機器人

Project Trillium-提供業(yè)界最具擴展性、應(yīng)用范圍最廣的機器學(xué)習(xí)計算平臺

焊接裂紋產(chǎn)生的機理,如何防治?

在STM32上使用機器學(xué)習(xí)算法進行動作識別

在嵌入式物聯(lián)網(wǎng)節(jié)點運行機器學(xué)習(xí)代碼,輕松識別物體

什么是TinyML?微型機器學(xué)習(xí)

什么是機器學(xué)習(xí)? 機器學(xué)習(xí)基礎(chǔ)入門

基于LabVIEW的鋼桿裂紋定量識別技術(shù)的研究

如何把握機器學(xué)習(xí)未來方向、趨勢和熱點

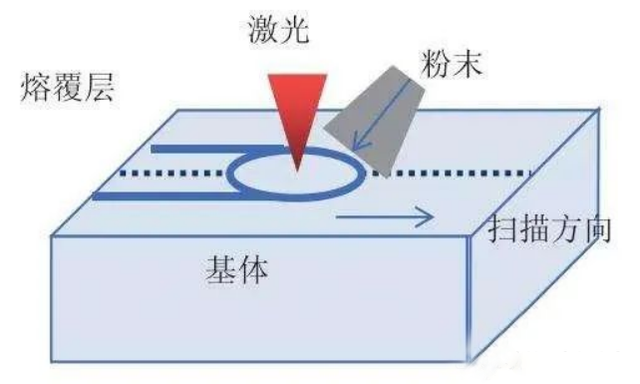

激光熔覆裂紋產(chǎn)生原因及裂紋分類

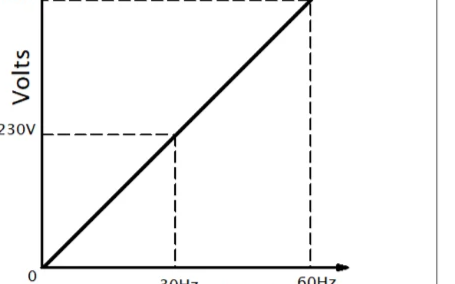

為什么使用電驅(qū)動?變頻驅(qū)動器如何控制扭矩/速度和方向

機器學(xué)習(xí)數(shù)據(jù)驅(qū)動中如何對小裂紋擴展的方向和速度進行識別

機器學(xué)習(xí)數(shù)據(jù)驅(qū)動中如何對小裂紋擴展的方向和速度進行識別

評論