After watching Space X explode 27 miles in the air over Cape Canaveral as it went supersonic, I’m looking for some good space news. Fortunately, the initial trials for the first additively manufactured ceramic catalyst bed have been successful. The team behind the trials, led by researchers at the University of Birmingham in England, believe that their new 3D printed ceramic thruster could significantly affect the longevity and the efficiency of space travel.

Historically, the city of Birmingham has been associated with manufacturing since before the Industrial Revolution. In 1791, it was even called “the first manufacturing town in the world.” Now, with funding from the ESA (European Space Agency), it looks like the University of Birmingham is on the forefront again of manufacturing technology, but, this time, they have 3D printed? enhanced catalyst bed thrusters that could launch us out of orbit.? The trials are the apex of several years of research and experiments using 3D printing technology to explore the potential for 3D space engineering and creating a new generation of rocket engines.

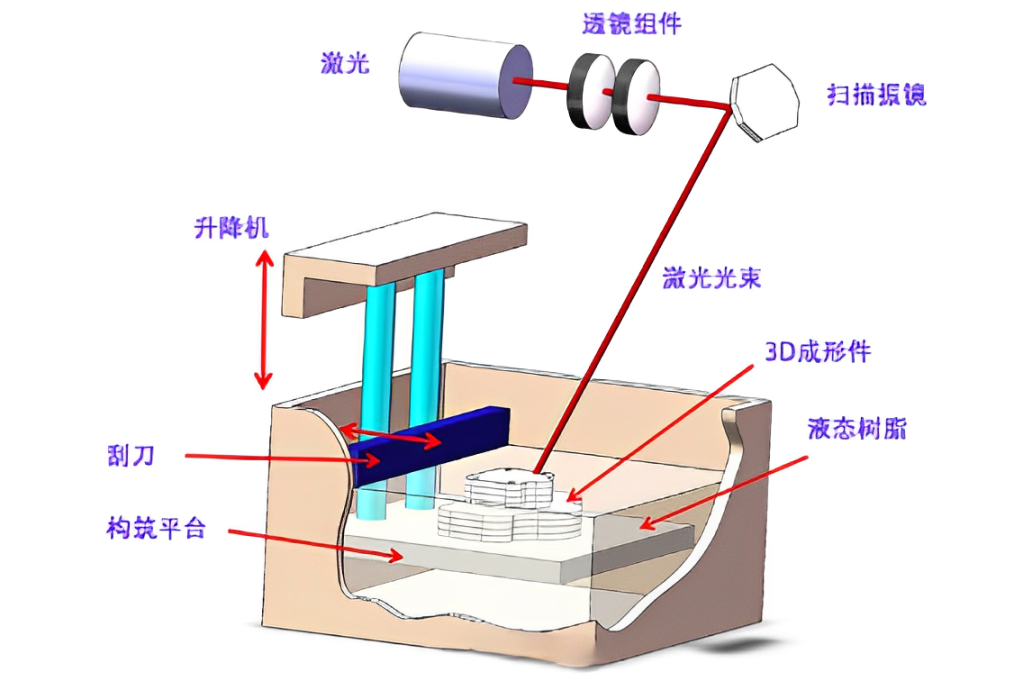

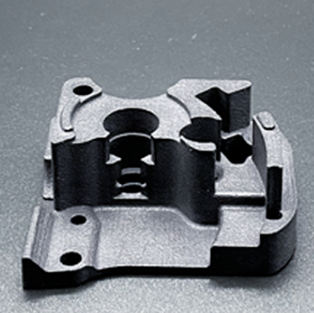

Through years of research into 3D printing practices, the research team has developed a new technique which can produce complex ceramic parts with a high surface area per unit mass and a resolution of 100 microns. With the help of their unique additive manufacturing and coating method, they were able to create monolithic catalyst beds that hold up nicely through various rounds of testing, led by Dr. Khamis Essa, Lecturer in Advanced Manufacturing at the University of Birmingham and the initial carried out by Dr. Hany Hassanin, a research Fellow in the School of Mechanical Engineering.? DELTACAT ltd. and the University of Southhampton helped the University of Birmingham develop the trials and tested the engine performance and the new design.

Some of the results: High and repeatable performance overall with and a non-toxic, environmentally sound hydrogen peroxide monopropellant.? Judging from the trials, it seems that University of Birmingham’s monolithic catalyst beds actually out-perform standard ceria pellets catalyst beds. According to the trials, the engine performance was a 20N thrust at 700oc, 3.5bar Pressure drop and 909m/s C* with 99% C* efficiency recorded. In other words, the catalyst beds were extremely reactive.

This 3D printed catalyst bed and all of the additive manufactured parts that are making their way through trials will certainly impact the space industry by encouraging innovative design and material use, increasing performance and compactness, aiding in lower production costs and in producing less overall waste in the manufacturing process. 3D printed products like the University of Birmingham’s catalyst bed, may take years to develop, but once they have a working prototype, can be additively manufactured very quickly so they can make an immediate impact on the market.

Dr. Khamis Essa said of their testing, “These results are truly impressive. The testing team indicated that they have never seen performance like this. I’m excited about developing such revolutionary new technology and look forward to seeing it make high impacts on the space industry.”

自動翻譯僅供參考

新型3D打印陶瓷推進器助力太空之旅 看著空間X爆炸27英里空氣過卡納維拉爾角,因為它去了超音速之后,我在尋找一些良好的空間的消息。幸運的是,對于第一相加地制造陶瓷催化劑床中的初步試驗獲得了成功。在試驗中,為首的研究人員在英國伯明翰英格蘭大學背后的團隊,相信他們的新的3D打印的陶瓷推進器能顯著影響壽命和太空旅行的效率。

3D測試印刷陶瓷推進器在南安普敦大學

從歷史上看,自從工業革命之前,伯明翰市就一直與制造業聯系在一起。在1791,它甚至被稱為“世界上第一個制造城市”。現在,在歐洲航天局(ESA)的資助下,伯明翰大學似乎再次處于制造技術的前沿,但這次,他們有3D打印的增強型CAT。我們可以用3D打印技術來探索3D空間工程的潛力和創造新一代的火箭引擎。

3D伯明翰大學印刷陶瓷催化劑bedThrough多年的研究3D打印實踐,研究小組已經開發出一種新技術,它可以產生復雜的陶瓷部件,每單位質量高表面積和100微米的分辨率。憑借其獨特的添加劑制造和涂裝方法的幫助下,他們能夠創建托起很好地通過多輪測試,帶領由哈米斯埃薩,講師博士在先進制造,在英國伯明翰大學和初始進行整體催化劑床由哈尼Hassanin博士,研究員機械工程學院。? DELTACAT有限公司。和南安普頓大學的幫助伯明翰大學開發的試驗和測試了發動機的性能和全新的設計。

一些結果: - 高和可重復的性能和總體非毒性,對環境無害的過氧化氫單組元推進劑。?從試驗情況來看,似乎大學伯明翰的整體式催化劑床實際上在性能標準的氧化鈰顆粒催化劑床。據試驗,發動機性能是20N推力在700℃,3.5巴的壓力降和909米/ s的C *與錄制了99%C *效率。換言之,在催化劑床都非常具有反應性。

先進材料加工-3本3D打印的催化劑床層和所有通過實驗使他們的方式制造的添加劑部分通過鼓勵創新的設計和材料的使用,提高性能和緊湊性,有助于降低生產成本肯定會影響到航天工業和在制造過程中產生較少的總的浪費。 3D打印產品,如伯明翰的催化劑床的大學,可能需要幾年時間來開發,但是一旦他們有一個工作原型,可以加和制造非常快,使他們能夠使市場產生直接影響。

哈米斯伊薩博士說,他們的測試,“這些結果是真正令人印象深刻。測試團隊表示,他們從來沒有見過像這樣的表現。我很興奮開發這種革命性的新技術,并期待著看到它使對航天事業高度的影響。“

-

3D打印

+關注

關注

27文章

3589瀏覽量

112416

發布評論請先 登錄

答疑|3D打印能打印立體字母嗎?

3D打印技術:如何讓古老文物重獲新生?

3D打印技術在材料、工藝方面的突破

有源晶振在3D打印機應用方案

3D打印技術應用的未來

應用在3D打印機的BD系列金屬連接器

3D打印汽車零部件建模設計3D打印服務

新型3D打印陶瓷推進器助力太空之旅

新型3D打印陶瓷推進器助力太空之旅

評論